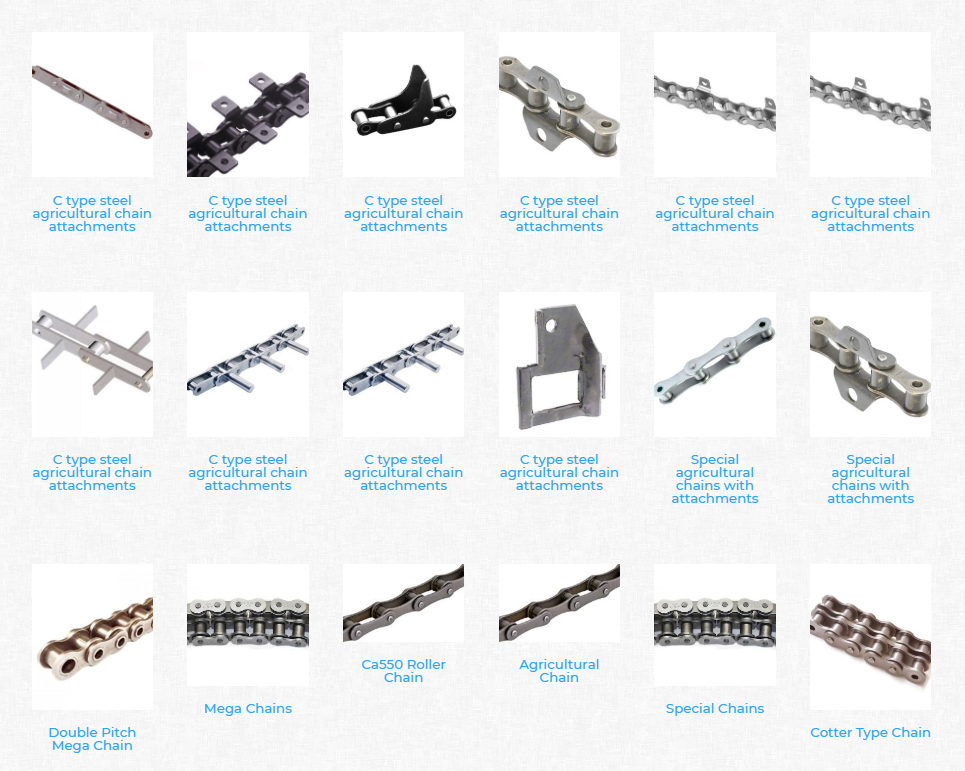

Product Description

Steel 45# Thickness 7mm Chain Gear Kit Set Motorcycles Parts Sprocket

Product Description

ALL SIZE:

1.BAJAJ100: 428H-42T-14T-112L

2.AX100: 428H-42T-14T-112L

3. CGL125: 428H-38T-15T-116L

4. CGL125: 428H-41T-15T-116L

5. CGL125: 428H-42T-15T-116L

6. TVS STAR: 428H-40T-13T-116L

7. TVS HLX: 428H-40T-14T-116L

8. CD110: 428H-36T-14T-112L

9.BX100: 428H-42T-14T-112L

10.GN125: 428H-42T-15T-116L

11.WIN100: 428H-41T-14T-120L

12.CB100: 428H-39T-14T-108L

MACHINES AND EXHIBITIONS

Stable and perfect quality will help you get good reputation in your market and obtain more orders and cooperations.:

| Size | Standard |

| Material | 45# STEEL |

| Thickness | 7MM |

| Brand Name | YANGMU Or OEM |

| Products range | motorcycle, tricycle , scooter , |

| Place of Origin | HangZhou, China |

| Certificate | CCC; DOT; E-MARK; SNI; INMETRO; CNAS; ISO; SONCAP; SGS |

| Main Market | Middle East, Southeast Asia, Africa, South America, Europe, America |

| Payment term | T/T; L/C; |

| MOQ | 500PCS |

| Production Capacity | 5000 Pieces/day |

| Delivery Time | 30 days |

| Package | Color Bag then Carton Boxes |

SPROCKET SIZE

SPROCKET KIT PACKINGT

MOTORCYCLE TYRE PATTERN

WAREHOUSE AND LOADING

Our Advantage

1. Are you a factory or a trading company?

HangZhou Xihu (West Lake) Dis.da Industrial Products Co., Ltd is a professional factory.

2. Is OEM available?

Yes, OEM is available. We have professional designer to help your brand promotion.

3. Is the sample available?

Yes, samples are available for you to test the quality.

4. Are the products tested before shipping?

Yes, all of our tyre and inner tube were qualified before shipping.

We test every batch every day.

5. Whats your quality guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem

Welcome to contact us for more information.

Tony Xue

| After-sales Service: | Guarantee Replacement |

|---|---|

| Warranty: | Guarantee Replacement |

| Type: | Sprocket |

| Material: | Steel |

| Certification: | ISO9001:2001 |

| Number of Row: | Single Row |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Helical, Straight-Cut, and Spiral-Bevel Gears

If you are planning to use bevel gears in your machine, you need to understand the differences between Helical, Straight-cut, and Spiral bevel gears. This article will introduce you to these gears, as well as their applications. The article will also discuss the benefits and disadvantages of each type of bevel gear. Once you know the differences, you can choose the right gear for your machine. It is easy to learn about spiral bevel gears.

Spiral bevel gear

Spiral bevel gears play a critical role in the aeronautical transmission system. Their failure can cause devastating accidents. Therefore, accurate detection and fault analysis are necessary for maximizing gear system efficiency. This article will discuss the role of computer aided tooth contact analysis in fault detection and meshing pinion position errors. You can use this method to detect problems in spiral bevel gears. Further, you will learn about its application in other transmission systems.

Spiral bevel gears are designed to mesh the gear teeth more slowly and appropriately. Compared to straight bevel gears, spiral bevel gears are less expensive to manufacture with CNC machining. Spiral bevel gears have a wide range of applications and can even be used to reduce the size of drive shafts and bearings. There are many advantages to spiral bevel gears, but most of them are low-cost.

This type of bevel gear has three basic elements: the pinion-gear pair, the load machine, and the output shaft. Each of these is in torsion. Torsional stiffness accounts for the elasticity of the system. Spiral bevel gears are ideal for applications requiring tight backlash monitoring and high-speed operations. CZPT precision machining and adjustable locknuts reduce backlash and allow for precise adjustments. This reduces maintenance and maximizes drive lifespan.

Spiral bevel gears are useful for both high-speed and low-speed applications. High-speed applications require spiral bevel gears for maximum efficiency and speed. They are also ideal for high-speed and high torque, as they can reduce rpm without affecting the vehicle’s speed. They are also great for transferring power between two shafts. Spiral bevel gears are widely used in automotive gears, construction equipment, and a variety of industrial applications.

Hypoid bevel gear

The Hypoid bevel gear is similar to the spiral bevel gear but differs in the shape of the teeth and pinion. The smallest ratio would result in the lowest gear reduction. A Hypoid bevel gear is very durable and efficient. It can be used in confined spaces and weighs less than an equivalent cylindrical gear. It is also a popular choice for high-torque applications. The Hypoid bevel gear is a good choice for applications requiring a high level of speed and torque.

The Hypoid bevel gear has multiple teeth that mesh with each other at the same time. Because of this, the gear transmits torque with very little noise. This allows it to transfer a higher torque with less noise. However, it must be noted that a Hypoid bevel gear is usually more expensive than a spiral bevel gear. The cost of a Hypoid bevel gear is higher, but its benefits make it a popular choice for some applications.

A Hypoid bevel gear can be made of several types. They may differ in the number of teeth and their spiral angles. In general, the smaller hypoid gear has a larger pinion than its counterpart. This means that the hypoid gear is more efficient and stronger than its bevel cousin. It can even be nearly silent if it is well lubricated. Once you’ve made the decision to get a Hypoid bevel gear, be sure to read up on its benefits.

Another common application for a Hypoid bevel gear is in automobiles. These gears are commonly used in the differential in automobiles and trucks. The torque transfer characteristics of the Hypoid gear system make it an excellent choice for many applications. In addition to maximizing efficiency, Hypoid gears also provide smoothness and efficiency. While some people may argue that a spiral bevel gear set is better, this is not an ideal solution for most automobile assemblies.

Helical bevel gear

Compared to helical worm gears, helical bevel gears have a small, compact housing and are structurally optimized. They can be mounted in various ways and feature double chamber shaft seals. In addition, the diameter of the shaft and flange of a helical bevel gear is comparable to that of a worm gear. The gear box of a helical bevel gear unit can be as small as 1.6 inches, or as large as eight cubic feet.

The main characteristic of helical bevel gears is that the teeth on the driver gear are twisted to the left and the helical arc gears have a similar design. In addition to the backlash, the teeth of bevel gears are twisted in a clockwise and counterclockwise direction, depending on the number of helical bevels in the bevel. It is important to note that the tooth contact of a helical bevel gear will be reduced by about ten to twenty percent if there is no offset between the two gears.

In order to create a helical bevel gear, you need to first define the gear and shaft geometry. Once the geometry has been defined, you can proceed to add bosses and perforations. Then, specify the X-Y plane for both the gear and the shaft. Then, the cross section of the gear will be the basis for the solid created after revolution around the X-axis. This way, you can make sure that your gear will be compatible with the pinion.

The development of CNC machines and additive manufacturing processes has greatly simplified the manufacturing process for helical bevel gears. Today, it is possible to design an unlimited number of bevel gear geometry using high-tech machinery. By utilizing the kinematics of a CNC machine center, you can create an unlimited number of gears with the perfect geometry. In the process, you can make both helical bevel gears and spiral bevel gears.

Straight-cut bevel gear

A straight-cut bevel gear is the easiest to manufacture. The first method of manufacturing a straight bevel gear was to use a planer with an indexing head. Later, more efficient methods of manufacturing straight bevel gears were introduced, such as the Revacycle system and the Coniflex system. The latter method is used by CZPT. Here are some of the main benefits of using a straight-cut bevel gear.

A straight-cut bevel gear is defined by its teeth that intersect at the axis of the gear when extended. Straight-cut bevel gears are usually tapered in thickness, with the outer part being larger than the inner portion. Straight-cut bevel gears exhibit instantaneous lines of contact, and are best suited for low-speed, static-load applications. A common application for straight-cut bevel gears is in the differential systems of automobiles.

After being machined, straight-cut bevel gears undergo heat treatment. Case carburizing produces gears with surfaces of 60-63 Rc. Using this method, the pinion is 3 Rc harder than the gear to equalize wear. Flare hardening, flame hardening, and induction hardening methods are rarely used. Finish machining includes turning the outer and inner diameters and special machining processes.

The teeth of a straight-cut bevel gear experience impact and shock loading. Because the teeth of both gears come into contact abruptly, this leads to excessive noise and vibration. The latter limits the speed and power transmission capacity of the gear. On the other hand, a spiral-cut bevel gear experiences gradual but less-destructive loading. It can be used for high-speed applications, but it should be noted that a spiral-cut bevel gear is more complicated to manufacture.

Spur-cut bevel gear

CZPT stocks bevel gears in spiral and straight tooth configurations, in a range of ratios from 1.5 to five. They are also highly remachinable except for the teeth. Spiral bevel gears have a low helix angle and excellent precision properties. CZPT stock bevel gears are manufactured using state-of-the-art technologies and know-how. Compared with spur-cut gears, these have a longer life span.

To determine the strength and durability of a spur-cut bevel gear, you can calculate its MA (mechanical advantage), surface durability (SD), and tooth number (Nb). These values will vary depending on the design and application environment. You can consult the corresponding guides, white papers, and technical specifications to find the best gear for your needs. In addition, CZPT offers a Supplier Discovery Platform that allows you to discover more than 500,000 suppliers.

Another type of spur gear is the double helical gear. It has both left-hand and right-hand helical teeth. This design balances thrust forces and provides extra gear shear area. Helical gears, on the other hand, feature spiral-cut teeth. While both types of gears may generate significant noise and vibration, helical gears are more efficient for high-speed applications. Spur-cut bevel gears may also cause similar effects.

In addition to diametral pitch, the addendum and dedendum have other important properties. The dedendum is the depth of the teeth below the pitch circle. This diameter is the key to determining the center distance between two spur gears. The radius of each pitch circle is equal to the entire depth of the spur gear. Spur gears often use the addendum and dedendum angles to describe the teeth.

editor by CX 2023-04-19

China Cgl125 428h-38t-15t-116L Cheap Price Nigeria Manufactory Chain Kit Wheel Set Motorcycles Spare Parts Sprocket Gear bevel gear set

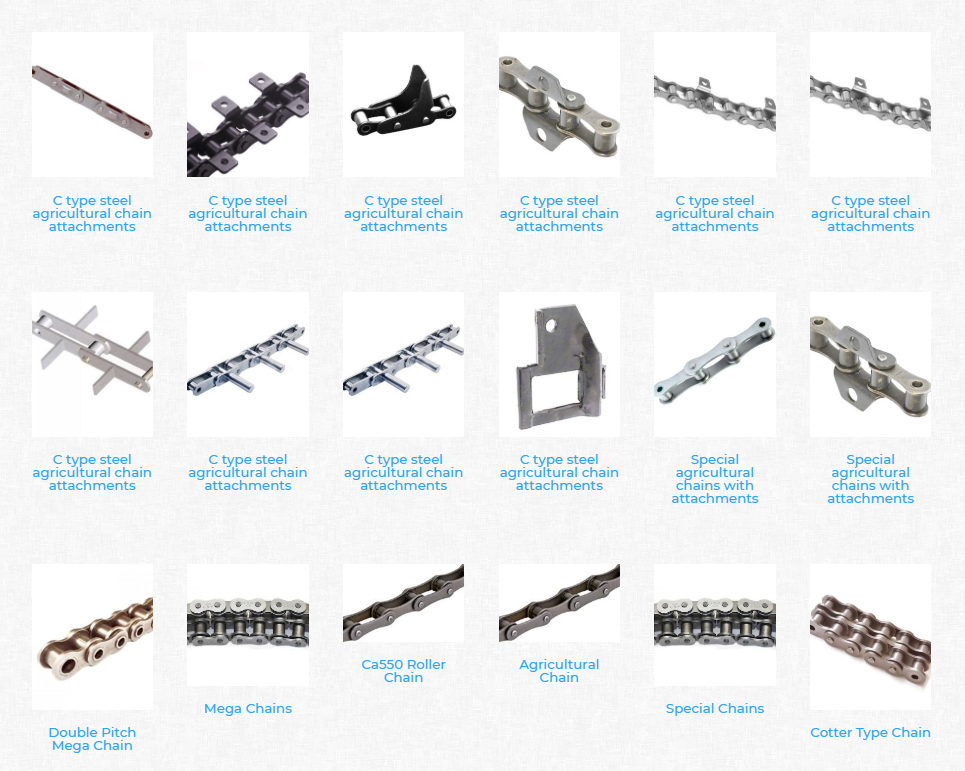

Solution Description

Chain Equipment Kit Wheel Established Bikes Spare Components Sprocket

Item Description

ALL Dimensions:

one. BAJAJ100 428H-42T-14T-112L

2. AX100 428H-42T-14T-112L

3. CGL125 428H-38T-15T-116L

four. CGL125 428H-41T-15T-116L

five. CGL125 428H-42T-15T-116L

six. TVS STAR 428H-40T-13T-116L

7. TVS HLX 428H-40T-14T-116L

8. CD110 428H-36T-14T-112L

nine. BX100 428H-42T-14T-112L

10. GN125 428H-42T-15T-116L

eleven. WIN100 428H-41T-14T-120L

12. CB100 428H-39T-14T-108L

Machines AND EXHIBITIONS

Steady and excellent high quality will aid you get good reputation in your market and acquire far more orders and cooperations.:

| Dimension | Regular |

| Material | 45# Steel |

| Thickness | 7MM |

| Model Title | YANGMU Or OEM |

| Items variety | motorcycle, tricycle , scooter , |

| Location of Origin | HangZhou, China |

| Certification | CCC DOT E-MARK SNI INMETRO CNAS ISO SONCAP SGS |

| Main Industry | Middle East, Southeast Asia, Africa, South The usa, Europe, The usa |

| Payment term | T/T L/C |

| MOQ | 500PCS |

| Manufacturing Capability | 5000 Pieces/working day |

| Shipping Time | thirty times |

| Bundle | Color Bag then Carton Bins |

SPROCKET SIZE

SPROCKET Package PACKINGT

Motorbike TYRE Sample

Motorcycle TYRE PACKING AND LOADING

Our Gain

one. Are you a factory or a trading organization?

HangZhou Xihu (West Lake) Dis.da Industrial Merchandise Co., Ltd is a professional manufacturing facility.

2. Is OEM available?

Indeed, OEM is available. We have skilled designer to aid your brand marketing.

3. Is the sample available?

Of course, samples are offered for you to check the quality.

four. Are the goods analyzed ahead of shipping?

Yes, all of our tyre and interior tube were experienced prior to shipping and delivery.

We examination each batch each and every working day.

five. Whats your good quality promise?

We have one hundred% top quality promise to buyers. We will be liable for any good quality dilemma

Welcome to speak to us for more information.

Tony Xue

|

/ Piece | |

50 Pieces (Min. Order) |

###

| After-sales Service: | Guarantee Replacement |

|---|---|

| Warranty: | Guarantee Replacement |

| Type: | Sprocket |

| Material: | Steel |

| Certification: | ISO9001:2001 |

| Number of Row: | Single Row |

###

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| Size | Standard |

| Material | 45# STEEL |

| Thickness | 7MM |

| Brand Name | YANGMU Or OEM |

| Products range | motorcycle, tricycle , scooter , |

| Place of Origin | Qingdao, China |

| Certificate | CCC; DOT; E-MARK; SNI; INMETRO; CNAS; ISO; SONCAP; SGS |

| Main Market | Middle East, Southeast Asia, Africa, South America, Europe, America |

| Payment term | T/T; L/C; |

| MOQ | 500PCS |

| Production Capacity | 5000 Pieces/day |

| Delivery Time | 30 days |

| Package | Color Bag then Carton Boxes |

|

/ Piece | |

50 Pieces (Min. Order) |

###

| After-sales Service: | Guarantee Replacement |

|---|---|

| Warranty: | Guarantee Replacement |

| Type: | Sprocket |

| Material: | Steel |

| Certification: | ISO9001:2001 |

| Number of Row: | Single Row |

###

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| Size | Standard |

| Material | 45# STEEL |

| Thickness | 7MM |

| Brand Name | YANGMU Or OEM |

| Products range | motorcycle, tricycle , scooter , |

| Place of Origin | Qingdao, China |

| Certificate | CCC; DOT; E-MARK; SNI; INMETRO; CNAS; ISO; SONCAP; SGS |

| Main Market | Middle East, Southeast Asia, Africa, South America, Europe, America |

| Payment term | T/T; L/C; |

| MOQ | 500PCS |

| Production Capacity | 5000 Pieces/day |

| Delivery Time | 30 days |

| Package | Color Bag then Carton Boxes |

Types of Bevel Gears

Bevel Gears are used in a number of industries. They are used in wheeled excavators, dredges, conveyor belts, mill actuators, and rail transmissions. A bevel gear’s spiral or angled bevel can make it suitable for confined spaces. It is also used in robotics and vertical supports of rolling mills. You can use bevel gears in food processing processes. For more information on bevel gears, read on.

Spiral bevel gear

Spiral bevel gears are used to transmit power between two shafts in a 90-degree orientation. They have curved or oblique teeth and can be fabricated from various metals. Bestagear is one manufacturer specializing in medium to large spiral bevel gears. They are used in the mining, metallurgical, marine, and oil fields. Spiral bevel gears are usually made from steel, aluminum, or phenolic materials.

Spiral bevel gears have many advantages. Their mesh teeth create a less abrupt force transfer. They are incredibly durable and are designed to last a long time. They are also less expensive than other right-angle gears. They also tend to last longer, because they are manufactured in pairs. The spiral bevel gear also reduces noise and vibration from its counterparts. Therefore, if you are in need of a new gear set, spiral bevel gears are the right choice.

The contact between spiral bevel gear teeth occurs along the surface of the gear tooth. The contact follows the Hertz theory of elastic contact. This principle holds for small significant dimensions of the contact area and small relative radii of curvature of the surfaces. In this case, strains and friction are negligible. A spiral bevel gear is a common example of an inverted helical gear. This gear is commonly used in mining equipment.

Spiral bevel gears also have a backlash-absorbing feature. This feature helps secure the thickness of the oil film on the gear surface. The shaft axis, mounting distance, and angle errors all affect the tooth contact on a spiral bevel gear. Adjusting backlash helps to correct these problems. The tolerances shown above are common for bevel gears. In some cases, manufacturers make slight design changes late in the production process, which minimizes the risk to OEMs.

Straight bevel gear

Straight bevel gears are among the easiest types of gears to manufacture. The earliest method used to manufacture straight bevel gears was to use a planer equipped with an indexing head. However, improvements have been made in manufacturing methods after the introduction of the Revacycle system and the Coniflex. The latest technology allows for even more precise manufacturing. Both of these manufacturing methods are used by CZPT. Here are some examples of straight bevel gear manufacturing.

A straight bevel gear is manufactured using two kinds of bevel surfaces, namely, the Gleason method and the Klingelnberg method. Among the two, the Gleason method is the most common. Unlike other types of gear, the CZPT method is not a universal standard. The Gleason system has higher quality gears, since its adoption of tooth crowning is the most effective way to make gears that tolerate even small assembly errors. It also eliminates the stress concentration in the bevelled edges of the teeth.

The gear’s composition depends on the application. When durability is required, a gear is made of cast iron. The pinion is usually three times harder than the gear, which helps balance wear. Other materials, such as carbon steel, are cheaper, but are less resistant to corrosion. Inertia is another critical factor to consider, since heavier gears are more difficult to reverse and stop. Precision requirements may include the gear pitch and diameter, as well as the pressure angle.

Involute geometry of a straight bevel gear is often computed by varying the surface’s normal to the surface. Involute geometry is computed by incorporating the surface coordinates and the theoretical tooth thickness. Using the CMM, the spherical involute surface can be used to determine tooth contact patterns. This method is useful when a roll tester tooling is unavailable, because it can predict the teeth’ contact pattern.

Hypoid bevel gear

Hypoid bevel gears are an efficient and versatile speed reduction solution. Their compact size, high efficiency, low noise and heat generation, and long life make them a popular choice in the power transmission and motion control industries. The following are some of the benefits of hypoid gearing and why you should use it. Listed below are some of the key misperceptions and false assumptions of this gear type. These assumptions may seem counterintuitive at first, but will help you understand what this gear is all about.

The basic concept of hypoid gears is that they use two non-intersecting shafts. The smaller gear shaft is offset from the larger gear shaft, allowing them to mesh without interference and support each other securely. The resulting torque transfer is improved when compared to conventional gear sets. A hypoid bevel gear is used to drive the rear axle of an automobile. It increases the flexibility of machine design and allows the axes to be freely adjusted.

In the first case, the mesh of the two bodies is obtained by fitting the hyperboloidal cutter to the desired gear. Its geometric properties, orientation, and position determine the desired gear. The latter is used if the desired gear is noise-free or is required to reduce vibrations. A hyperboloidal cutter, on the other hand, meshes with two toothed bodies. It is the most efficient option for modeling hypoid gears with noise concerns.

The main difference between hypoid and spiral bevel gears is that the hypoid bevel gear has a larger diameter than its counterparts. They are usually found in 1:1 and 2:1 applications, but some manufacturers also provide higher ratios. A hypoid gearbox can achieve speeds of three thousand rpm. This makes it the preferred choice in a variety of applications. So, if you’re looking for a gearbox with a high efficiency, this is the gear for you.

Addendum and dedendum angles

The addendum and dedendum angles of a bevel gear are used to describe the shape and depth of the teeth of the gear. Each tooth of the gear has a slightly tapered surface that changes in depth. These angles are defined by their addendum and dedendum distances. Addendum angle is the distance between the top land and the bottom surface of the teeth, while dedendum angle is the distance between the pitch surface and the bottom surface of the teeth.

The pitch angle is the angle formed by the apex point of the gear’s pitch cone with the pitch line of the gear shaft. The dedendum angle, on the other hand, is the depth of the tooth space below the pitch line. Both angles are used to measure the shape of a bevel gear. The addendum and dedendum angles are important for gear design.

The dedendum and addendum angles of a bevel gear are determined by the base contact ratio (Mc) of the two gears. The involute curve is not allowed to extend within the base diameter of the bevel gear. The base diameter is also a critical measurement for the design of a gear. It is possible to reduce the involute curve to match the involute curve, but it must be tangential to the involute curve.

The most common application of a bevel gear is the automotive differential. They are used in many types of vehicles, including cars, trucks, and even construction equipment. They are also used in the marine industry and aviation. Aside from these two common uses, there are many other uses for bevel gears. And they are still growing in popularity. But they’re a valuable part of automotive and industrial gearing systems.

Applications of bevel gears

Bevel gears are used in a variety of applications. They are made of various materials depending on their weight, load, and application. For high-load applications, ferrous metals such as grey cast iron are used. These materials have excellent wear resistance and are inexpensive. For lower-weight applications, steel or non-metals such as plastics are used. Some bevel gear materials are considered noiseless. Here are some of their most common uses.

Straight bevel gears are the easiest to manufacture. The earliest method of manufacturing them was with a planer with an indexing head. Modern manufacturing methods introduced the Revacycle and Coniflex systems. For industrial gear manufacturing, the CZPT uses the Revacycle system. However, there are many types of bevel gears. This guide will help you choose the right material for your next project. These materials can withstand high rotational speeds and are very strong.

Bevel gears are most common in automotive and industrial machinery. They connect the driveshaft to the wheels. Some even have a 45-degree bevel. These gears can be placed on a bevel surface and be tested for their transmission capabilities. They are also used in testing applications to ensure proper motion transmission. They can reduce the speed of straight shafts. Bevel gears can be used in many industries, from marine to aviation.

The simplest type of bevel gear is the miter gear, which has a 1:1 ratio. It is used to change the axis of rotation. The shafts of angular miter bevel gears can intersect at any angle, from 45 degrees to 120 degrees. The teeth on the bevel gear can be straight, spiral, or Zerol. And as with the rack and pinion gears, there are different types of bevel gears.

editor by CX 2023-03-30

China Chain Wheel Milling Machining Auto Mobile Parts Gear raw gear

Product Description

|

Product Identify |

cnc machining auto mobile parts |

|

Material |

Steel / aluminum alloy/Stainless steel/Copper/Plastic |

|

Measurement |

In accordance to customers’ prerequisite. |

|

Standard |

DIN GB ISO JIS BA ANSI |

|

Processing |

one, Indication Drawing (General clientele supply the drawing or samples) |

|

Test Equipment |

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge and so on. |

|

Application |

Automotive, instrument, electrical tools, house appliances, furniture, mechanical gear, everyday living products, digital sporting activities tools, light industry merchandise, sanitation machinery, and so forth. |

|

Tolerance |

+/-.01mm-+/-.05mm |

1.Q:Are you investing business or manufacturer?

A: We are manufacturing unit with a lot more then 15years knowledge

two.Q: How long is your delivery time?

A: Typically it is 15-30days as we are Custom-made service we validate with Buyer

when spot buy

3.Q:Do you offer samples? ls it free of charge or additional?

A: Of course we give samples .for sample cost as per sample condition to make a decision cost-free

or billed ,typically for not also considerably time employed consumed machining procedure are free

4.Q:What is your phrases of payment?

thirty% T/T in advance harmony ahead of cargo .Or as for each discussion

five.Q: Can we know the generation approach without going to the manufacturing unit?

A:We will supply comprehensive manufacturing timetable and send out weekly studies with digital photographs

and movies which display the machining progress

6.Q:Obtainable for personalized layout drawings?

A: YesDWG.DXF.DXW.IGES.Phase. PDF etc

7.Q:Available for custom-made design drawings?

A: Yes ,we can indicator the NDA prior to your ship the drawing

8.Q:How do you assure the high quality?

A:(1) Examining the uncooked materials soon after they get to our manufacturing unit——

Incoming good quality handle(IQC)

(2) Examining the particulars just before the generation line operated

(3) Have a complete inspection and routing inspection in the course of mass creation—

In-approach top quality control(IPQC)

(4) Checking the goods soon after they are completed—- Closing high quality handle(FQC)

(5) Examining the merchandise soon after they are completed—–Outgoing top quality handle(QC)

(6)100% inspection and shipping and delivery ahead of shipment.

|

US $0.5-2 / Piece | |

100 Pieces (Min. Order) |

###

| Condition: | New |

|---|---|

| Certification: | CE, GS, ISO9001 |

| Standard: | DIN, GB |

| Customized: | Customized |

| Material: | Stainless Steel ; Carbon Steel ; Alloy ; Aluminum |

| Application: | Metal Cutting Machine, Metal Processing Machinery Parts, Metal forging Machinery, Metal Drawing Machinery, Industry |

###

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

|

Product Name

|

cnc machining auto mobile parts |

|

Material

|

Steel / aluminum alloy/Stainless steel/Copper/Plastic

Any other material and dimension depends on customers’ demand. |

|

Size

|

According to customers’ requirement.

|

|

Standard

|

DIN GB ISO JIS BA ANSI

|

|

Processing

|

1, Sign Drawing (General clients provide the drawing or samples)

2, Precision Machining: Burring, Chamfering, Lathe, CNC milling and turning, Drilling, Grinding, Bending, Stamping, Tapping, etc 3, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing,Rust preventive oil. 4, Inspection and Packing |

|

Test Equipment

|

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc.

|

|

Application

|

Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, etc.

|

|

Tolerance

|

+/-0.01mm-+/-0.05mm

|

|

US $0.5-2 / Piece | |

100 Pieces (Min. Order) |

###

| Condition: | New |

|---|---|

| Certification: | CE, GS, ISO9001 |

| Standard: | DIN, GB |

| Customized: | Customized |

| Material: | Stainless Steel ; Carbon Steel ; Alloy ; Aluminum |

| Application: | Metal Cutting Machine, Metal Processing Machinery Parts, Metal forging Machinery, Metal Drawing Machinery, Industry |

###

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

|

Product Name

|

cnc machining auto mobile parts |

|

Material

|

Steel / aluminum alloy/Stainless steel/Copper/Plastic

Any other material and dimension depends on customers’ demand. |

|

Size

|

According to customers’ requirement.

|

|

Standard

|

DIN GB ISO JIS BA ANSI

|

|

Processing

|

1, Sign Drawing (General clients provide the drawing or samples)

2, Precision Machining: Burring, Chamfering, Lathe, CNC milling and turning, Drilling, Grinding, Bending, Stamping, Tapping, etc 3, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing,Rust preventive oil. 4, Inspection and Packing |

|

Test Equipment

|

Measurement instrument, Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc.

|

|

Application

|

Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment, daily living equipment, electronic sports equipment, light industry products, sanitation machinery, etc.

|

|

Tolerance

|

+/-0.01mm-+/-0.05mm

|

Spiral Gears for Right-Angle Right-Hand Drives

Spiral gears are used in mechanical systems to transmit torque. The bevel gear is a particular type of spiral gear. It is made up of two gears that mesh with one another. Both gears are connected by a bearing. The two gears must be in mesh alignment so that the negative thrust will push them together. If axial play occurs in the bearing, the mesh will have no backlash. Moreover, the design of the spiral gear is based on geometrical tooth forms.

Equations for spiral gear

The theory of divergence requires that the pitch cone radii of the pinion and gear be skewed in different directions. This is done by increasing the slope of the convex surface of the gear’s tooth and decreasing the slope of the concave surface of the pinion’s tooth. The pinion is a ring-shaped wheel with a central bore and a plurality of transverse axes that are offset from the axis of the spiral teeth.

Spiral bevel gears have a helical tooth flank. The spiral is consistent with the cutter curve. The spiral angle b is equal to the pitch cone’s genatrix element. The mean spiral angle bm is the angle between the genatrix element and the tooth flank. The equations in Table 2 are specific for the Spread Blade and Single Side gears from Gleason.

The tooth flank equation of a logarithmic spiral bevel gear is derived using the formation mechanism of the tooth flanks. The tangential contact force and the normal pressure angle of the logarithmic spiral bevel gear were found to be about twenty degrees and 35 degrees respectively. These two types of motion equations were used to solve the problems that arise in determining the transmission stationary. While the theory of logarithmic spiral bevel gear meshing is still in its infancy, it does provide a good starting point for understanding how it works.

This geometry has many different solutions. However, the main two are defined by the root angle of the gear and pinion and the diameter of the spiral gear. The latter is a difficult one to constrain. A 3D sketch of a bevel gear tooth is used as a reference. The radii of the tooth space profile are defined by end point constraints placed on the bottom corners of the tooth space. Then, the radii of the gear tooth are determined by the angle.

The cone distance Am of a spiral gear is also known as the tooth geometry. The cone distance should correlate with the various sections of the cutter path. The cone distance range Am must be able to correlate with the pressure angle of the flanks. The base radii of a bevel gear need not be defined, but this geometry should be considered if the bevel gear does not have a hypoid offset. When developing the tooth geometry of a spiral bevel gear, the first step is to convert the terminology to pinion instead of gear.

The normal system is more convenient for manufacturing helical gears. In addition, the helical gears must be the same helix angle. The opposite hand helical gears must mesh with each other. Likewise, the profile-shifted screw gears need more complex meshing. This gear pair can be manufactured in a similar way to a spur gear. Further, the calculations for the meshing of helical gears are presented in Table 7-1.

Design of spiral bevel gears

A proposed design of spiral bevel gears utilizes a function-to-form mapping method to determine the tooth surface geometry. This solid model is then tested with a surface deviation method to determine whether it is accurate. Compared to other right-angle gear types, spiral bevel gears are more efficient and compact. CZPT Gear Company gears comply with AGMA standards. A higher quality spiral bevel gear set achieves 99% efficiency.

A geometric meshing pair based on geometric elements is proposed and analyzed for spiral bevel gears. This approach can provide high contact strength and is insensitive to shaft angle misalignment. Geometric elements of spiral bevel gears are modeled and discussed. Contact patterns are investigated, as well as the effect of misalignment on the load capacity. In addition, a prototype of the design is fabricated and rolling tests are conducted to verify its accuracy.

The three basic elements of a spiral bevel gear are the pinion-gear pair, the input and output shafts, and the auxiliary flank. The input and output shafts are in torsion, the pinion-gear pair is in torsional rigidity, and the system elasticity is small. These factors make spiral bevel gears ideal for meshing impact. To improve meshing impact, a mathematical model is developed using the tool parameters and initial machine settings.

In recent years, several advances in manufacturing technology have been made to produce high-performance spiral bevel gears. Researchers such as Ding et al. optimized the machine settings and cutter blade profiles to eliminate tooth edge contact, and the result was an accurate and large spiral bevel gear. In fact, this process is still used today for the manufacturing of spiral bevel gears. If you are interested in this technology, you should read on!

The design of spiral bevel gears is complex and intricate, requiring the skills of expert machinists. Spiral bevel gears are the state of the art for transferring power from one system to another. Although spiral bevel gears were once difficult to manufacture, they are now common and widely used in many applications. In fact, spiral bevel gears are the gold standard for right-angle power transfer.While conventional bevel gear machinery can be used to manufacture spiral bevel gears, it is very complex to produce double bevel gears. The double spiral bevel gearset is not machinable with traditional bevel gear machinery. Consequently, novel manufacturing methods have been developed. An additive manufacturing method was used to create a prototype for a double spiral bevel gearset, and the manufacture of a multi-axis CNC machine center will follow.

Spiral bevel gears are critical components of helicopters and aerospace power plants. Their durability, endurance, and meshing performance are crucial for safety. Many researchers have turned to spiral bevel gears to address these issues. One challenge is to reduce noise, improve the transmission efficiency, and increase their endurance. For this reason, spiral bevel gears can be smaller in diameter than straight bevel gears. If you are interested in spiral bevel gears, check out this article.

Limitations to geometrically obtained tooth forms

The geometrically obtained tooth forms of a spiral gear can be calculated from a nonlinear programming problem. The tooth approach Z is the linear displacement error along the contact normal. It can be calculated using the formula given in Eq. (23) with a few additional parameters. However, the result is not accurate for small loads because the signal-to-noise ratio of the strain signal is small.

Geometrically obtained tooth forms can lead to line and point contact tooth forms. However, they have their limits when the tooth bodies invade the geometrically obtained tooth form. This is called interference of tooth profiles. While this limit can be overcome by several other methods, the geometrically obtained tooth forms are limited by the mesh and strength of the teeth. They can only be used when the meshing of the gear is adequate and the relative motion is sufficient.

During the tooth profile measurement, the relative position between the gear and the LTS will constantly change. The sensor mounting surface should be parallel to the rotational axis. The actual orientation of the sensor may differ from this ideal. This may be due to geometrical tolerances of the gear shaft support and the platform. However, this effect is minimal and is not a serious problem. So, it is possible to obtain the geometrically obtained tooth forms of spiral gear without undergoing expensive experimental procedures.

The measurement process of geometrically obtained tooth forms of a spiral gear is based on an ideal involute profile generated from the optical measurements of one end of the gear. This profile is assumed to be almost perfect based on the general orientation of the LTS and the rotation axis. There are small deviations in the pitch and yaw angles. Lower and upper bounds are determined as – 10 and -10 degrees respectively.

The tooth forms of a spiral gear are derived from replacement spur toothing. However, the tooth shape of a spiral gear is still subject to various limitations. In addition to the tooth shape, the pitch diameter also affects the angular backlash. The values of these two parameters vary for each gear in a mesh. They are related by the transmission ratio. Once this is understood, it is possible to create a gear with a corresponding tooth shape.

As the length and transverse base pitch of a spiral gear are the same, the helix angle of each profile is equal. This is crucial for engagement. An imperfect base pitch results in an uneven load sharing between the gear teeth, which leads to higher than nominal loads in some teeth. This leads to amplitude modulated vibrations and noise. In addition, the boundary point of the root fillet and involute could be reduced or eliminate contact before the tip diameter.

editor by czh 2022-12-14

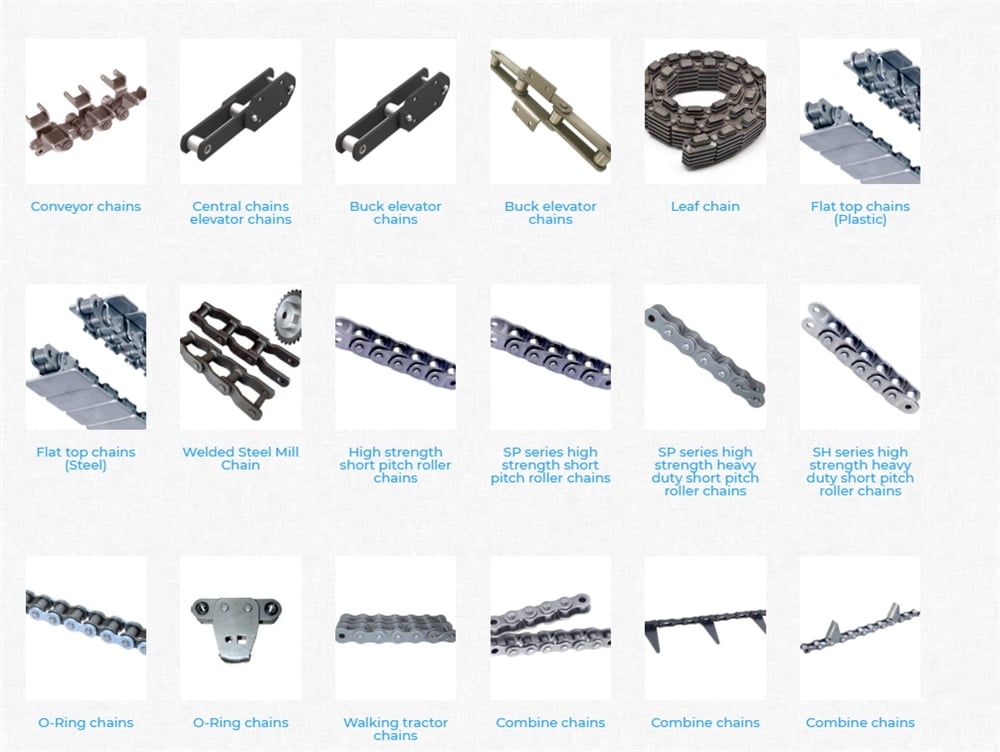

China Hot selling Pintle Chain AL667X-KSB AL667XH-KSB AL88XH-KSB wholesaler

Agricultural Steel Pintle Chain AL667X-KSB AL667XH-KSB AL88XH-KSB With KSB Attachment

EVER-POWER Steel Pintle Chain is designed for dependability and quality, at a great price.The Allied-Locke Steel Pintle Chain is well suited for a wide range of applications, such as salt- sand-fertilizer spreaders, bunk feeders, hay handling equip- ment and other similar conveying systems.

EVER-POWER Steel Pintle Chains feature all heat treated parts with quad staked pins.The open barrel construction minimizes pin surface contact with the barrel, eliminating freezing due to corrosion. The open barrel design elimi- nates material build up in the roots of sprock- ets. This assures smoother operation, uniform link wear, greater resistance to fatigue and longer service life.

|

Att. No. |

Chain No. |

we are specialised in producing Agricultural Roller Chain, Flat Top Chain,Caterpillar Track Chain,Hollow Pin Chain,Conveyor Chain for Beer Filling and Packing Line,Paver Chain,Attachment Sidebar Elevator Chain,Bucket Elevator Chain (Cement Mill Chain),Forging Scraper Chain,Loading Chain for Automobile Industry,Loading Chain for Metallurgical Industry,Conveyor Chain for Mine Machinery,Trencher Chain,Sugar Mill Chain,Double Flex Chain,etc. Welcome calls and emails to inquiry! Contact us: We care about our valued buyers, if you have any questions, our Customer Service staffs will be very glad to help you. We try our best to reply to your emails as soon as possible, however, due to high volume of daily incoming emails and time zone difference, we may not be able to reply your emails immediately. Please allow 24 business hours for us to response. in San Jose United States sales price shop near me near me shop factory supplier Custom Non-Standard Chain Sprocket Gear for Industry manufacturer best Cost Custom Cheap wholesaler

EPG is a specialist company and exporter that is anxious with the layout, growth and creation. EPG was awarded with “famous merchandise of Zhejiang Province” and “famous brand of Zhejiang Province”. Retaining in head that good support is the crucial to cooperating with clientele, we attempt to meet up with higher quality standards, provide competitive costs and make certain prompt supply. Item specification 2.EPTs can be manufactured in accordance the customer’s drawings three.Heat therapy: Hardening and Tempering, EPT Frequency Quenching, Carburizing Quenching and so on according the requirements.. 4. Inspection: All items are checked and analyzed extensively during every working method and after generation will be reinspected. About us The organization now has 80 sets of numerous large-precision CNC lathes, EPT hobbing EPTTs, EPT shapers, tempering furnaces, quenching products, gantry planers, EPT milling, sawing EPTTs, vertical broaching EPTTs, EPT EPTTs and other processing tools, with an once-a-year creation capability of 2 million items . Carburizing and quenching, nitriding, quenching and other warmth remedy, surface blackening, galvanizing, electrophoresis, and many others. At the very same time, it also has large-precision tests equipment this kind of as: Rockwell hardness tester, Vickers hardness tester, metallographic microscope, graphic measuring instrument, EPTic particle flaw detectors, and many others. The merchandise created are widely employed in metallurgy, metal, chemical, textile, agricultural EPTTry, three-dimensional XiHu (West EPT) Dis.Hu (West EPT) Dis.ages, EPTT EPTTry, chemical EPTTry, pharmaceutical EPTTry, EPTT and mining EPTTry and other EPTT. The product indicators fulfill the specifications of EPTTing comparable goods and are exported to EPT and EPTTiwan, SouthEPT Asia, Europe, America, the Center EPT and other areas, and are deeply EPTTed and praised by customers.

FAQ Q: How EPTT is your supply time?

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Primary specialized parameters | |||||

| EPTT variety | MS40 | MS50 | MS63 | MS80 | |

| Slot width (MM) | 400 | five hundred | 630 | 800 | |

| Nominal bearing depth (MM) | four hundred | 465 | 465 | 465 | |

| MaXiHu (West EPT) Dis.mum bearing depth (MM) | one hundred~250 | one hundred~three hundred | 100~350 | a hundred~350 | |

| Scraper EPT | Sort | 3006T Type Pitch200MM | |||

| Allowable load(KN) | a hundred and twenty | a hundred and twenty | a hundred and twenty | 120 | |

| Fat(KG/M) | 32.5 | 37.5 | forty two.5 | 50 | |

| Speed(M/S) | .08~.16 | ||||

| Fixed potential(T/H) | eight~40 | fifteen~sixty | twenty~eighty | thirty~one hundred ten | |

| MaXiHu (West EPT) Dis.mum EPTT length(M) | sixty | fifty | forty | thirty | |

| EPT EPTT(KW) | le11 | le15 | le18.5 | le22 | |

Working Basic principle

When Unitfine EPT scraper conveyor EPTT transports horizontally, the stress arrives from EPTs in conveying path to the resources, and the motion which arrives from the components them selves triggers inner friction. This friction guarantees the steady predicament amongst content layers, and it can get over external frictional resistance induced by transferring components in the trough and make resources transport as a EPTT fluid.

-It can several feed food and a lot more details out of materials.

-With a large boot gadget and an automated alarm system.

-The XiHu (West EPT) Dis.Hu (West EPT) Dis. rail is manufactured of EPTT material.

-The scraper blade is made of polyurethane material, simple to run, and prolong its doing work existence.

-EPTT for high strength high dress in resistance, EPTT conveying distance.

-The motor tail has EPTd design, effortless to work, it can prolong its functioning daily life.

-It is commonly utilized for port, pier, oil, chemical, grain, flour, malt, alcoholic beverages, semi-completed solution feed, and other materials.

EPTT ampSHIPPING

FAQ gt gt gt

one. What’s substance will be transported by EPTT Scraper EPTT EPTT for Cement?

Cement, sand, limestone, grain? And its max. temperature, lump dimensions, and density.

two. What is actually the potential of EPTT Scraper EPTT EPTT for Cement that you want?

20t/h, 50t/h, 100t/h?

3. How is duration outside the house diameter EPTT Scraper EPTT EPTT for Cement?

4. What is actually the tilt angle of EPTT Scraper EPTT EPTT for Cement?

5. Other EPTT needs?

Like very hot substance, SEW EPTT, EPT motor.

6. It truly is EPT if you have a layout drawing or sketch.

China manufacturer & factory supplier for china in Karaj Iran supplier Chain sprocket roller chain and sprocket kits transmission sprocket With high quality best price & service

EPG significant maker and supplier of ball bearings and energy transmission products. Given that it’s commencing in 1992, EPG has developed into one of the foremost suppliers in the market. Essential factors that have contributed to our growth is our devotion to the fundamentals of progressive style, competitive pricing, outstanding consumer services, and product availability. Meanwhile, our products are made in accordance to high top quality specifications, and complying with the intercontinental sophisticated standard conditions.

Overview

Swift Details

- Applicable Industries:

-

Developing Material Retailers, Producing Plant, Farms, Design works , Power & Mining, Foods & Beverage Shops

- Certification:

-

ISO9001

- Product title:

-

sprockets chain

- Software:

-

Transmission System

Provide Ability

- Source Potential:

- 20000 Piece/Items for each Thirty day period chain wheel

Packaging & Shipping

- Packaging Information

- industrial package

The EP Line PTO travel shafts are recognizable since of the EP Line patented coupling mechanism and the flexible cone. The PTO travel shafts are distinguished through user-friendliness, compactness and attractive design.

- Port

- Shanghai

On-line Customization

HangZhou Ever-Electricity transmission Co. Ltd. A single of branch of Ever-Electrical power Group – the greatest China transmisssion supplier. With 1200 employee and precision gear, we produce large high quality merchandise to Usa and EU and other locations.

Solution parameter

| British Regular Stainless Metal Roller Chain | ||||||||||||

| East Chain NO. | Pitch | Roller diameter | Inner width | Plate thickness | Plate depth | Pin diameter | Pin duration | Transvers | Breaking load | Weight for every meter | ||

| pitch | ||||||||||||

| P | d1 | b1 | T | h2 | d2 | L | LC | Pt | Q | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | daN | kg/m | ||

| 06B-2 | 9.525 | six.35 | five.seventy two | 1.two | eight | 3.27 | 23.4 | 24.four | ten.24 | 1240 | .eight | |

| 08B-two | 12.7 | 8.fifty one | 7.75 | one.five | twelve | 4.45 | 31.two | 32.2 | thirteen.92 | 2480 | one.four | |

| 10B-2 | 15.875 | ten.16 | nine.sixty five | two | fifteen | 5.08 | 36.1 | 37.five | 16.59 | 3100 | 1.nine | |

| 12B-two | 19.05 | 12.07 | 11.sixty eight | 2 | sixteen | five.72 | forty two | 43.six | 19.forty six | 4040 | 2.5 | |

| 16B-2 | twenty five.4 | fifteen.88 | 17.02 |

4/three |

21 | 8.28 | 68 | 69.three | 31.88 | 5920 | five.4 | |

| 20B-two | 31.seventy five | 19.05 | 19.fifty six | 5/four | 30 | 10.19 | 77.eight | eighty one.5 | 36.forty five | 11000 | 7.2 | |

| 24B-2 | 38.1 | 25.4 | twenty five.four | 6/five | 36 | 14.sixty three | 101.7 | 106.two | 48.36 | 17600 | 13.4 | |

| ANSI Regular Stainless Steel Roller Chain | ||||||||||||

| East | Pitch | Roller diameter | Inner width | Plate thickness | Plate depth | Pin Diameter | Pin duration | Transvers pitch | Breaking load | Weight for every meter | ||

| Chain NO. | ||||||||||||

| P | d1 | b1 | T | h2 | d2 | L | LC | Pt | Q | q | ||

| ANSI | ISO | mm | mm | mm | mm | mm | mm | mm | mm | mm | daN | kg/m |

| Feb-forty | 08A-two | 12.seven | seven.In near session with the client, the layout of special gearboxes and high-precision gearing factors are individually personalized to the technical and operational demands. For special needs these kinds of as High Speed, reduced sounds or Substantial TORQUE, we create optimal consumer remedies thanks to our several years of knowledge and experience. Additionally, we supply support in the assessment of load exams and product engineering optimization. Owing to our steadily creating skills, this benefits in tailor created higher-finish options, which we create in-house.ninety two | seven.85 | one.five | 12 | three.95 | 31 | 32.two | 14.38 | 1920 | 1.two |

| Feb-50 | 10A-2 | fifteen.875 | 10.sixteen | 9.4 | 2 | 15 | 5.08 | 38.9 | forty.4 | eighteen.11 | 3040 | 2 |

| Feb-60 | 12A-2 | 19.05 | eleven.9 | 12.fifty seven | two.5 | eighteen | 5.ninety four | forty eight.four | fifty.5 | 22.seventy eight | 4340 | 3 |

| Feb-80 | 16A-two | twenty five.four | 15.88 | 15.75 | three | 23 | 7.94 | sixty two.7 | 64.three | 29.29 | 7780 | five.two |

| a hundred-two | 20A-two | 31.seventy five | 19.05 | eighteen.nine | four | 30 | nine.5 | seventy six.4 | eighty.5 | 35.seventy six | 11800 | 7.six |

| one hundred twenty-2 | 24A-2 | 38.one | 22.two | twenty five.22 | five | 36 | 11.1 | ninety five.8 | 99.7 | 45.forty four | 16000 | 11.2 |

| a hundred and forty-2 | 28A-2 | 44.forty five | 25.four | twenty five.22 | 6 | 41.one | twelve.seven | 103.three | 107.nine | 48.87 | 19600 | 15 |

| one hundred sixty-two | 32A-2 | fifty.8 | 28.fifty eight | 31.55 | 6 | 48 | 14.27 | 123.three | 128.1 | 58.fifty five | 25000 | twenty.two |

| Short pitch transmission roller chain |

Double pitch transmission roller chain |

Leaf chain | Flank speak to slient chain |

||||

| ISO NO. | ANSI NO. | ISO NO. | ANSI NO. | ISO NO. | ANSI NO. | ANSI NO. | |

| 08A | forty | 208A | 2040 | LH0822 | BL422 | SC3 | |

| 10A | fifty | 210A | 2050 | LH0823 | BL423 | SC4 | |

| 12A | sixty | 212A | 2060 | LH0834 | BL434 | SC5 | |

| 16A | 80 | 216A | 2080 | LH0844 | BL444 | SC6 | |

| 20A | 100 | 220A | 2100 | LH0846 | BL446 | SC8 | |

| 24A | a hundred and twenty | 224A | 2120 | LH0866 | BL466 | SC10 | |

| 28A | 140 | … | … | LH0888 | BL488 | ||

| 32A | one hundred sixty | LH1022 | BL522 | ||||

| 36A | 180 | LH1023 | BL523 | ||||

| … | … | Double pitch conveyor roller chain |

… | … | Agriculture conveyor chain |

||

| 04B | C208A | C2040 | LH3234 | BL1634 | 81X | ||

| 05B | C208AL | C2042 | LH3244 | BL1644 | 81XH | ||

| 06B | C210A | C2050 | LH3246 | BL1646 | 81XHH | ||

| 08B | C210AL | C2052 | LH3266 | BL1666 | CA550 | ||

| 10B | C212 | C2060 | LH3288 | BL1688 | CA555 | ||

| 12B | C212AL | C2062 | LH4022 | BL2022 | CA620 | ||

| 16B | C212AH | C2060H | LH4023 | BL2023 | |||

| 20B | C212AHL | C2062H | LH4034 | BL2034 | |||

| 24B | C216A | C2080 | LH4044 | BL2044 | |||

| 28B | C216AL | C2082 | LH4046 | BL2046 | |||

| 32B | C216AH | C2080H | LH4066 | BL2066 | |||

| 40B | C216AHL | C2082H | LH4088 | BL2088 | |||

Please seek advice from us for any chains unlisted listed here.

Solution present

Connected bearing

Far more merchandise

Organization Profile

Founded in Could 1979, the yr when China began its open policy, we are a stated owned complete business combining “industry & buying and selling, technologies & trading”. In 2002, our business transformed from condition-owned company to non-public owned firm. Backed up by robust economic energy, advanced facilities & technological innovation, and large generation capability of several factories, Xinguang has been establishing speedily in company because its basis create extended- expression and helpful partnership with numerous consumers from most regions of the planet. Now, our personnel are much more than sixty, in which half of them are engineers. Almost certainly what tends to make us diverse from other trading companies is that we have a distinctive workers of both businessmen and skilled mechanical engineers, who have been operating in the business for a long time. This function of us functions an crucial position in quality administration, cost management, and support efficiency.

certificate

Sprocket Cost made in China – replacement parts – in Barquisimeto Venezuela for Plastic Conveyor Chain 820-K325 with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 distinct branches. For more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Product specification

one.Materials:C 45# metal ,stainless steel or EPT needed resources.

two.Sprockets can be manufactured in accordance the customer’s drawings

3.Warmth treatment method: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on according the specifications..

4. Inspection: All items are checked and tested extensively throughout every functioning method and following generation will be reinspected.

About us

HangZhou EPT Sprocket Co., Ltd. is a skilled manufacturer of various sprocket wheels, stainless steel sprocket wheels, non-regular sprocket wheels, massive pitch sprocket wheels, coupling sprocket wheels, spur gears, timing belt wheels, gear racks, umbrella Equipment, worm gear, shaft, sleeve and EPT transmission elements manufacturers. And in accordance to client drawings, samples, measurement processing custom made manufacturing. The firm integrates design R & D, manufacturing and sales. In accordance with rigid manufacturing, inspection and high quality expectations, the organization has set up a extensive quality program, generation method and ideal top quality management. The firm’s sprocket items are of substantial quality, stability and longevity.

The business now has eighty sets of various higher-precision CNC lathes, equipment hobbing equipment, gear shapers, tempering furnaces, quenching tools, gantry planers, common milling, sawing devices, vertical broaching equipment, hydraulic machines and EPT processing gear, with an once-a-year creation ability of 2 million parts . Carburizing and quenching, nitriding, quenching and EPT warmth remedy, surface area blackening, galvanizing, electrophoresis, and many others. At the identical time, it also has substantial-precision tests gear this sort of as: Rockwell hardness tester, Vickers hardness tester, metallographic microscope, impression measuring instrument, Magnetic particle flaw detectors, and so on. The merchandise produced are broadly utilised in metallurgy, metal, chemical, textile, agricultural equipment, a few-dimensional garages, packaging machinery, chemical machinery, pharmaceutical equipment, industrial and mining machinery and EPT industries. The product indicators meet the specifications of importing related merchandise and are exported to Hong Kong and ZheJiang , Southea EPT Asia, Europe, The united states, the Middle Ea EPT and EPT regions, and are deeply reliable and praised by clients.

FAQ

Q: Are you buying and selling organization or manufacturer ?

A: We are manufacturing unit.

Q: How extended is your delivery time?

A: Usually it is 5-10 times if the goods are in inventory. or it is fifteen-twenty times if the products are not in inventory, it is according to amount.

Q: Do you provide samples ? is it totally free or added ?

A: Of course, we could offer you the sample for free of charge charge but do not pay out the co EPT of freight.

Q: What is your phrases of payment ?

A: Payment 30%TT in advance. 70% T/T before shippment.

Q:What`s the MOQ of your merchandise?

A:1 established,we can also deal with the sample buy. and the big-quantity.

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 diverse branches. For more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of unique products manufacturer’s (OEM) element quantities or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our company and the shown replacement elements contained herein are not sponsored, authorized, or made by the OEM.

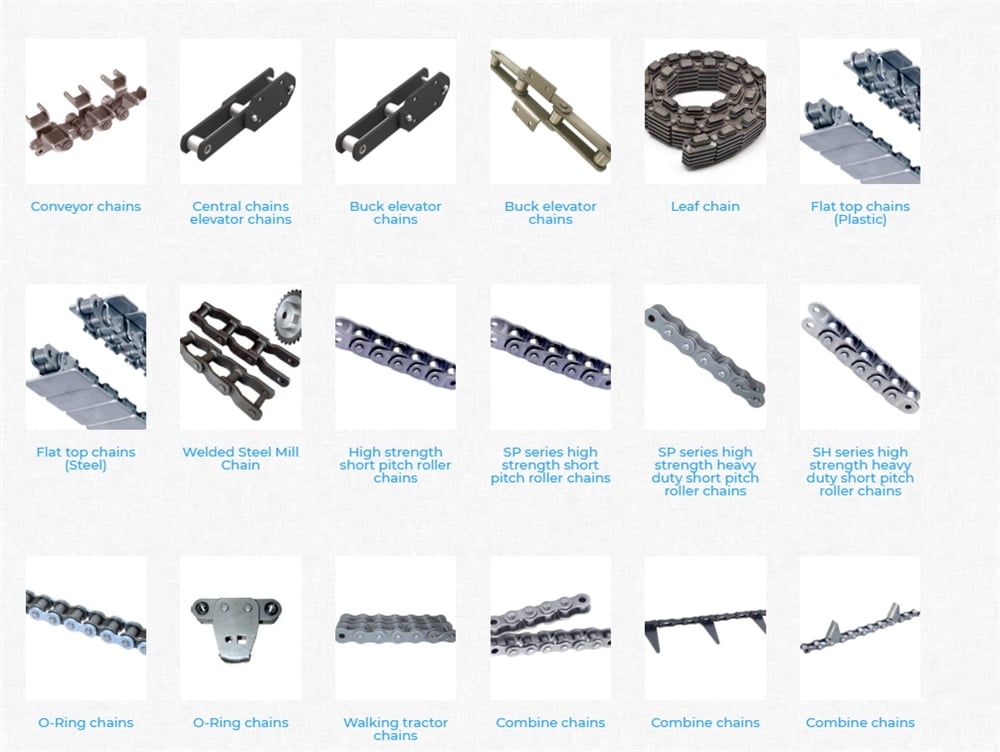

China manufacturer & factory supplier for Various in Zarqa Jordan high quality OEM chain supply with ISO9001:2015 With high quality best price & service

No other variety of chains can defeat EPG for range. In addition to traditional roller chains of all sorts and measurements, roller chains with attachments and double pitch roller chains, we also offer you specific chains this sort of as grip chains, accumulation chains, elastomeric profile chains, leaf chains, bushed conveyor chains, hollow pin chains and numerous other models. Upkeep-free of charge or corrosion-evidence chains are offered for special applications. Our pin oven chains and tube conveyor chains permit a wide range of answers for the effective creation and optimum conveying of cans and tubes. Find out far more about our productEPG has been efficiently qualified by ISO9002 Good quality Administration Method, ISO9001 Quality Administration System, API certificate, ISO/TS16949:2002 and ISO10012 measurement management method.

Overview

Swift Particulars

- Relevant Industries:

-

Manufacturing Plant

- Standard or Nonstandard:

-

Normal

- Variety:

-

Roller Chain

- Materials:

-

ALLOY

- Tensile Strength:

-

Strong

- Spot of Origin:Zhejiang, China

- Brand name Identify:

-

OEM

- Design Number:

-

A lot of types or Types

- Merchandise name:

-

A variety of high quality OEM chain source with ISO9001:2015

- OEM:

-

Available

- Samples:

-

Offered

- Trial Get:

-

Obtainable

- Packaging:

-

Can be personalized

- Coloration:

-

Mother nature

- Certification:

-

ISO9001:2015

- Perform:

-

Transmisssion

- Payment:

-

T/T,L/C,D/A,D/P,Western Union

Offer Capability

- Offer Potential:

- 100000 Meter/Meters per Month Different higher high quality OEM chain provide with ISO9001:2015

Packaging & Shipping

- Packaging Details

- Or as customer’s demand for Numerous high top quality OEM chain provide with ISO9001:2015″>Pallet, Veneer Circumstance, Wood Case

Or as customer’s require for A variety of large quality OEM chain provide with ISO9001:2015

- Port

- Shanghai

Online Customization

Numerous substantial quality OEM chain offer with ISO9001:2015

Specs

one. Reduced price tag

two. Higher Top quality

three. Greatest Services

4. Fast shipping and delivery

Solution Description

28years concentrating in Conveyor Chain ,emphasis on production conveyor chains which mainlyplay in the adhering to industries: cement business, Cane Sugar Milling Vegetation, Palm Oilmills, Water therapy industry , Mining market and so on. If the item is to beapplied in corrosive atmosphere.We advise youWe warmly welcome the buddies from all the planet! deciding on our car industrytransmission Chain with Stainless Steel ,as effectively as 17-4PH ,SS420HT ,Chrome plating.

1) Our Roller Chains are as subsequent goods:

·A series roller chain

·B series Roller chain

·Brief Pitch Conveyor Roller Chain With Attachments

·Roller Chain For Oil Fielid

·Heavy Collection Roller Chain

·Double Pitch Roller Chain

·AB Sequence Straight Sidebar Roller Chain

·Agricultural Roll Chain and attachment

·Hefty Duty Offset Sidebar Chain

·Shart Top Chain

two) Our Conveyor Chains are as subsequent items:

·FV Series Conveyor chain

·FVT Collection Conveyor chain

·FVC Collection Hollow Pin Shaft Conveyor Chain

·M Series Conveyor chain

·MT Series Conveyor chain

·MC Sequence Hollow Pin Shaft Conveyor Chain

·Double Pitch Conveyor Roller Chain

·Chain For Automobile,Design Equipment Ground Assembly Line

·Coating The Chain Conveyors

·WM Variety Prolonged Pitch Straight Sidebar Conveyor Chain

·Z Collection Conveyor Chain

·ZC Collection Hollow Pin Shaft Conveyor Chain

·ZE Series Conveyor Chain

·Hollow Pin Chain

·Sugar Chain

·Palm Oil Chain

·Metal Pintle Chain

·FL Conveyor Chain

·SDB Conveyor Chain

·SDBF Conveyor Chain

·DS Conveyor Chain

·NE Elevator Chain

·NSE Elevator Chain

·Feeding Chain

·Solid Chain

·Fall Cast Rivetless Chain

·Scraper Chain

·Cast Link

·Tobacco Machine Chain

·Lumber Conveyor Chain

·Rice Harvester Chain

three) Our Welded chains are as following goods:

·Slim Sequence Welded Chain

·Narrow Collection Welded Chain with attachment

·Welded Straight Sidebar Chain

·Broad Sequence Welded Chain

·Broad Collection Welded Chain with attachment

|

Item identify |

Different substantial top quality OEM chain source with ISO9001:2015 |

|

OEM |

Obtainable |

|

Samples |

Accessible |

|

Demo Order |

Obtainable |

|

Packing |

Can be personalized |

|

Color |

Mother nature |

|

Certification |

ISO9001:2008 |

|

Perform |

Transmission |

|

Payment |

T/T,L/C,D/A,D/P, Western Union |

|

Treatment method |

Warmth Therapy |

|

Content |

Alloy Steel |

|

Regular |

DIN GB ISO JIS BA ANSI |

|

Brand name |

At any time-Electrical power or OEM |

High quality Control

This is our quality control:

Packaging & Shipping and delivery

FAQ

Why chose us??

1. We are engaged in chain market for 28yrs with rich market experience. We maintain improving creation tactics. All the items have more time doing work existence and have handed the market take a look at.

2. According to abrasion resistance, corrosion, strengthen doing work daily life, we can layout the chains for you on every single business.

We can layout the appropriate chains with large good quality material, excellent abrasion resistance, excellent corrosion, large improve and and so on as per your ask for or the chain software

3. We are the chain manufacturer you can immediately buy the product from us with reduced price and higher high quality.

We are the chain manufacturer, you can get the goods with reduced value and substantial quality

4. We have a specialist crew for intercontinental trade, they have ample experiences and are constantly ready to solve difficulties for clients. So you have nothing at all to fear about.

five. We have the prolonged-term cooperative forwarder who can give us the least expensive freight. And it can help you to help save the freight. What is a lot more, for the FCL, we will style the offers as per the container sizes with the premier capacity to conserve the transport price for both of us.

Firm Info

ZheJiang At any time-Energy Chain Transmission Co., Ltd is 1 of the national large-scale manufacturers who emphasis on conveyor, transmission, drag and different special, abnormity, non-standard chains. Our business occupies far more than a hundred,000 sq. meters, and the set asset is far more than RMB 80,000,000 . Now the once-a-year production capabilities is over 3,000.000 meters, possessing far more than 600 sets of stamping, chilly rolling, finish machining, warmth remedy production equipments and take a look at devices etc. Our goods are exported to Europe, United states, Japan, Canada, South The united states, Southeast AsThe worm is made of casehardened quenched steel, with floor-on enamel sides, and the wheel is created of DIN (GZ-CuSn twelve Ni2) centricast bronze, melted on steel. Because of to the quality of these two areas mechanical functions, this sequence delivers superb efficiency and minimal sound amounts.ia, Africa, the Middle East and other nations and areas. Broadly employed in automobile plant and engineering equipment conveyor line, coating conveyor line, metallurgy, ports, electrical power, grain and oil, constructing materials, mining, cement, drying, petroleum, tobacco, environmental safety, forestry, electronics, textile, agriculture, foods, sugar, ceramics , beer filling equipment, Water treatment method, Crawler asphalt, palm oil and so forth. win a higher admiration and is broadly trustworthy at house and overseas.

Our firm has an abundant technological innovation, entirely generation equipments, superior technology and ideal detection techniques. Choose higher top quality alloy steel and undertake sophisticated warmth remedy, and recognized a complete top quality assurance program. It was licensed with GB/T19001-2008idt ISO9001:2008.High top quality “Ever-Power” brand name chains are accord with the Countrywide standard and International standard in all engineering indexes. And “Ever-Power” have been awarded as ZheJiang HangZhouFamous Model and ZheJiang HangZhouFamous Model Merchandise. “Quality initial, buyers first” is our goal, and we constantly give our services to domestic and overseas consumers warmly and cautiously.

Purposes

Our Providers

Provider:

· we will ship you all inquiries in 1 day.

· As new product,the mould can be free of charge if the volume more than USD20,000.

· As our Sincere clients,we can make the chains without minium amount.

· The supply time is 6 weeks.

· The samples can be despatched for free as aid you to open up the market.

speak to

If you waAdding a next engine basically is not sensible, which helps make electrical power get off (PTO) a beneficial component in providing power to secondary capabilities. To recognize their worth calls for a much better knowing of these methods, their different types, and their a variety of purposes.nt to know much more,you can go to our site:http://planetary-gearboxes.en.alibaba.com